-

Cynthia ZaneEasy to communicate and very professional. Good packaging.

Cynthia ZaneEasy to communicate and very professional. Good packaging. -

Gus VerduzcoGreat company and team. The product quality is good, and the after-sales team is very responsible

Gus VerduzcoGreat company and team. The product quality is good, and the after-sales team is very responsible -

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento -

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento

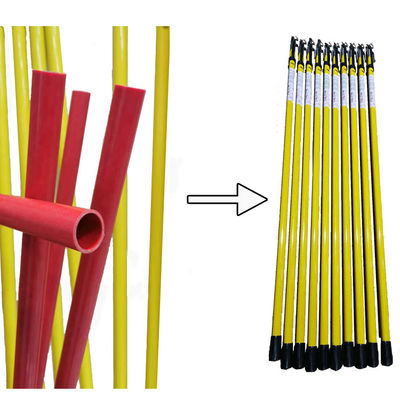

Smooth Epoxy Fiberglass Tube Knitting And Pultruded / Hollow Fiberglass Tube

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | High Voltage | Surface Treatment | Smooth Surface |

|---|---|---|---|

| Technique | Weaving And Pultrusion Process | Standard | IEC 60855, IEC 61235, ASTM F711 |

| Port | Shanghai Or Other Port In China | Material | Fiberglass |

| Brand | TID POWER | ||

| Highlight | Smooth Epoxy Fiberglass Tube,Epoxy Fiberglass Tube Knitting ISO9001,Knitting And Pultruded Hollow Fiberglass Tube |

||

Smooth Epoxy Fiberglass Tube Knitting And Pultruded / Hollow Fiberglass Tube

Product

1.The feature of Smooth Epoxy Fiberglass Tube Knitting And Pultruded / Hollow Fiberglass Tube

Tubes using glass fiber as insulation material have good insulation performance and mechanical strength. It is typically used for power system isolation and protection of wires, cables, or pipelines. The manufacturing process of glass fiber insulated hollow pipes generally includes the following steps:

1. Glass fiber preparation: Select suitable glass fiber materials, usually using E glass fiber (E-Glass) or S glass fiber (S-Glass). Glass fibers can be continuous or chopped fibers.

2. Fiber weaving: Weaving glass fibers to form a hollow tubular structure. Weaving can adopt different weaving methods and densities to achieve the required insulation performance and strength.

3. Adhesive coating: Apply adhesive to the woven glass fiber tube to enhance the bonding force and overall strength between fibers.

4. Curing: After coating with adhesive, the glass fiber pipe is cured, usually using heat treatment or chemical curing methods to ensure the stability and strength of the insulation pipe.

5. Cutting and shaping: Cut the cured fiberglass insulation pipe into the required length and perform necessary shaping treatment to ensure that the size and appearance of the pipe meet the requirements.

6. Inspection and testing: Conduct quality inspection and performance testing on glass fiber insulated pipes, such as electrical insulation performance, mechanical strength, etc. Glass fiber insulated hollow pipes have excellent electrical insulation, heat resistance, and corrosion resistance

|

No. |

Description |

Unit |

Value |

|

|

1 |

Density |

g/cm3 |

≥ 2.2 |

|

|

2. |

Water absorption rate |

% |

≤ 0.05 |

|

|

3 |

Dielectric dissipation factor at 50HZ |

|

≤ 0.0057 |

|

|

4 |

Penetration Test |

|

Non-penetration |

|

|

5 |

Dielectric tests before and after exposure to humidity |

Tests before exposure to humidity |

µA |

≤5.1 |

|

Tests after exposure to Humidity |

µA |

≤8.1 |

||

|

6 |

Dielectric wet test |

|

No flashover no sparkover or puncture: No visual sign of tracking or erosion on the surface ,both internal and external; No perceptible temperature rise |

|

|

7 |

Bending Test(Ø32mm) |

mm |

Deflection:f≤19.22 |

|

|

|

Proportion of Residual deflection to deflection measured during application of the force: Fd:≤0.41 |

|||

|

N |

Breacking Load:≥ 2635 |

|||

|

% |

The deflection variation under the same load in different directionsΔf:≤1.95 |

|||

|

8 |

Torsion Test(Ø32mm) |

|

Angle deflection ad<17.6 |

|

|

N.m |

Breacking Torsion:87.9 |

|||

|

9 |

Crushing Test(Ø32mm) |

N |

Min value where the first discontinuity of the curve occurs Fd>1771 |

|

|

N |

Max value during the first 3 min Fr>2785 |

|||

|

10 |

Mechanical fatigue tests |

4000times bending cycles test |

|

No visible damage,no permanet set. |

|

Dielectric tests before exposure to fumidity |

µA |

≤5.0 |

||

|

Dielectric tests after exposure to humidity |

µA |

≤8.2 |

||

|

11 |

Vesual Check |

|

Smooth appearance and no cracking |

|

2 More information of Smooth Epoxy Fiberglass Tube Knitting And Pultruded / Hollow Fiberglass Tube

Fiberglass insulated hollow tubes have excellent electrical insulation, heat resistance, and corrosion resistance. They can effectively isolate and protect wires, cables, or pipelines, reducing the risk of electrical leakage and mechanical damage. When using glass fiber insulated hollow pipes, appropriate specifications and installation methods should be selected according to specific requirements, and relevant installation standards and specifications should be followed

![]()

![]()

FAQ:

1.Is your company a manufacturer or a trader?

* We are the manufacture, 15 years production experience;

* our factory has passed ROSH, SGS, etc;

* Standard: IEC standard;

* Have own quanlity control.

2.Do you have export experience?

* More than 10 years export experience.

*TID products have been exported to Indonesia, Britain, Russia, Ukraine, Qatar, Romania, UAE, Egypt, USA, Costa rica ,Brazil etc.

3.Delivery time?

*Samples: 3-7 days; order: 30 days or according to the order quantity.

4.Do you accept OEM/ODM?

* Yes, we have several customer ask OEM/ODM, we'll do what you tell us!

Choose US, We shall provide you with all-round technical service!

We warmly welcome you to join us!

We are eager to keep permanent cooperation with you!