-

Cynthia ZaneEasy to communicate and very professional. Good packaging.

Cynthia ZaneEasy to communicate and very professional. Good packaging. -

Gus VerduzcoGreat company and team. The product quality is good, and the after-sales team is very responsible

Gus VerduzcoGreat company and team. The product quality is good, and the after-sales team is very responsible -

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento -

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento

Edson Polli juniorexcelente brillo, ahora a ver funciónamiento

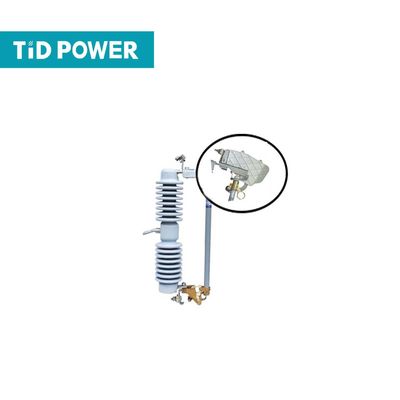

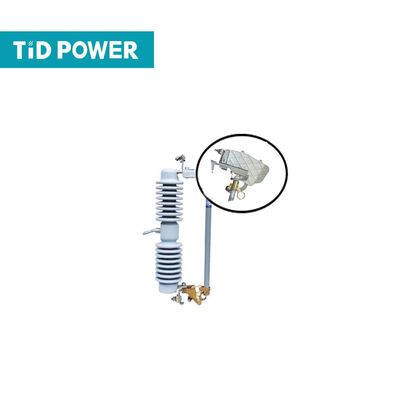

High Voltage Polymer Fuse Circuit Breaker / Composite Drop Fuse Cutout

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Place Of Origin | Shaan Xi, China | Application | Protective Device |

|---|---|---|---|

| Safety Standards | IEC | Product Name | Fuse Cutout |

| Rated Voltage | 40.5KV | Parts | Insulation Base (or Support Component), Contacts, Melt |

| Highlight | High Voltage Fuse Circuit Breaker,Ceramic Drop Out Fuse Cutout,Polymer Drop Out Fuse Cutout |

||

High Voltage Polymer Fuse Circuit Breaker / Composite Drop Fuse Cutout

Product:

1. The features of High Voltage Polymer Fuse Circuit Breaker / Composite Drop Fuse Cutout

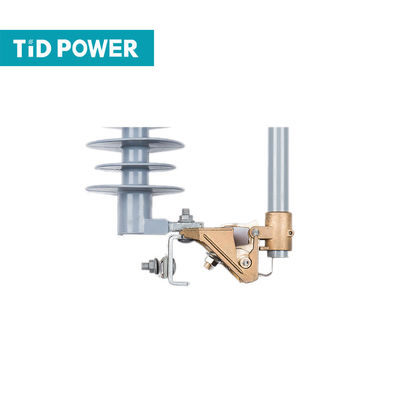

The fuse is mainly composed of three parts: the melt, the shell, and the support, among which the melt is a key component that controls the fusing characteristics. The material, size, and shape of the melt determine the fusing characteristics. Melt materials are divided into two categories: low melting point and high melting point. Low melting point materials such as lead and lead alloys have a low melting point and are prone to melting. Due to their high electrical resistivity, the cross-sectional size of the melt produced is larger, and the metal vapor generated during melting is more. They are only suitable for fuses with low breaking capacity. High melting point materials such as copper and silver have a high melting point and are not easy to fuse. However, due to their low electrical resistivity, they can be made into smaller cross-sectional sizes than low melting point melts. They produce less metal vapor during melting and are suitable for fuses with high breaking capacity. The shape of the melt can be divided into two types: filamentous and banded. Changing the shape of the variable cross-section can significantly change the fusing characteristics of the fuse. Fuses have various different fusing characteristic curves, which can be suitable for the needs of different types of protection objects.

2. The technical parameter of High Voltage Polymer Fuse Circuit Breaker / Composite Drop Fuse Cutout

HRW5-40.5kV Cutout Fuse

| Product Model | HRW5-40.5/100 | HRW5-40.5/200 |

| Rated Voltage(kV) | 40.5 | 40.5 |

| Rated Cutrent(A) | 100 | 200 |

| Breaking Current(VA),Up limit | 400 | 800 |

| Breaking Current(VA),Down limit | 10 | 30 |

| P.F. Dry Withstand Voltage(kV) | 105 | 105 |

| P.F. Wet Withstand Voltage(kV) | 185 |

185 |

| Allowed temperature rise except fuse live parts | 60 | 60 |

![]()

3. Good Raw material

-

We use HTV silicone rubber which hydrophobicity can reach to HC1 level

-

We use hot dip Galvanizing steel fitting ,the thickness of the zinc more than 100 μm

-

We use ECR rod as the core which is high acid resistant. 7200Hr testing passed.

4. Our service:

-

Free sample available

-

24 hours on-line service

-

Timely delivery

-

Free technical support

-

Long term after-sales service